Foodstuffs

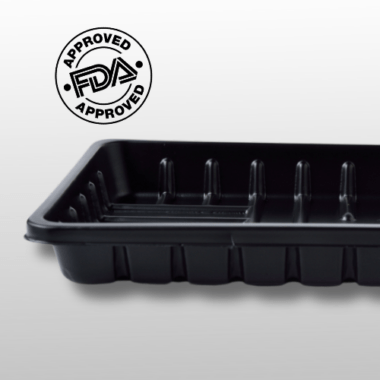

[PUR] for contact with food! Thanks to an approval according to diverse EU directives, we can offer you a first-class material in the shape of our cast PUR Intec E for extreme applications in contact with foodstuffs. Whether for one-offs or large-volume components weighing up to 900 kg, Intec E covers the entire range of hardness values from 45 to 93 Shore A. If you need large numbers of parts for foodstuffs applications, we can supply injection-moulded items made from approved materials weighing up to 6 kg and with an area of up to 1.5 m².

All our polyurethane systems conform to the REACH guidelines. [PUR] Intec E is our most abrasion-resistant material and so you get a double advantage: approval for your application and at the same time a material that is much better than the plastics currently in use! Benefit from this advantage.

Injection moulding allows us to implement various options for conforming to foodstuffs requirements. [PUR] is not the only trump card here! We can even supply a glass fibre-reinforced material with foodstuffs approval which you could employ to replace stainless steel. Simply ask our experts.

We will be happy to supply your components with a stainless steel core or in the form of an injection-moulded two-component part.

Take a look at the current Declaration of Conformity and simply ask if you require further information. Because: [PUR] is in our DNA.

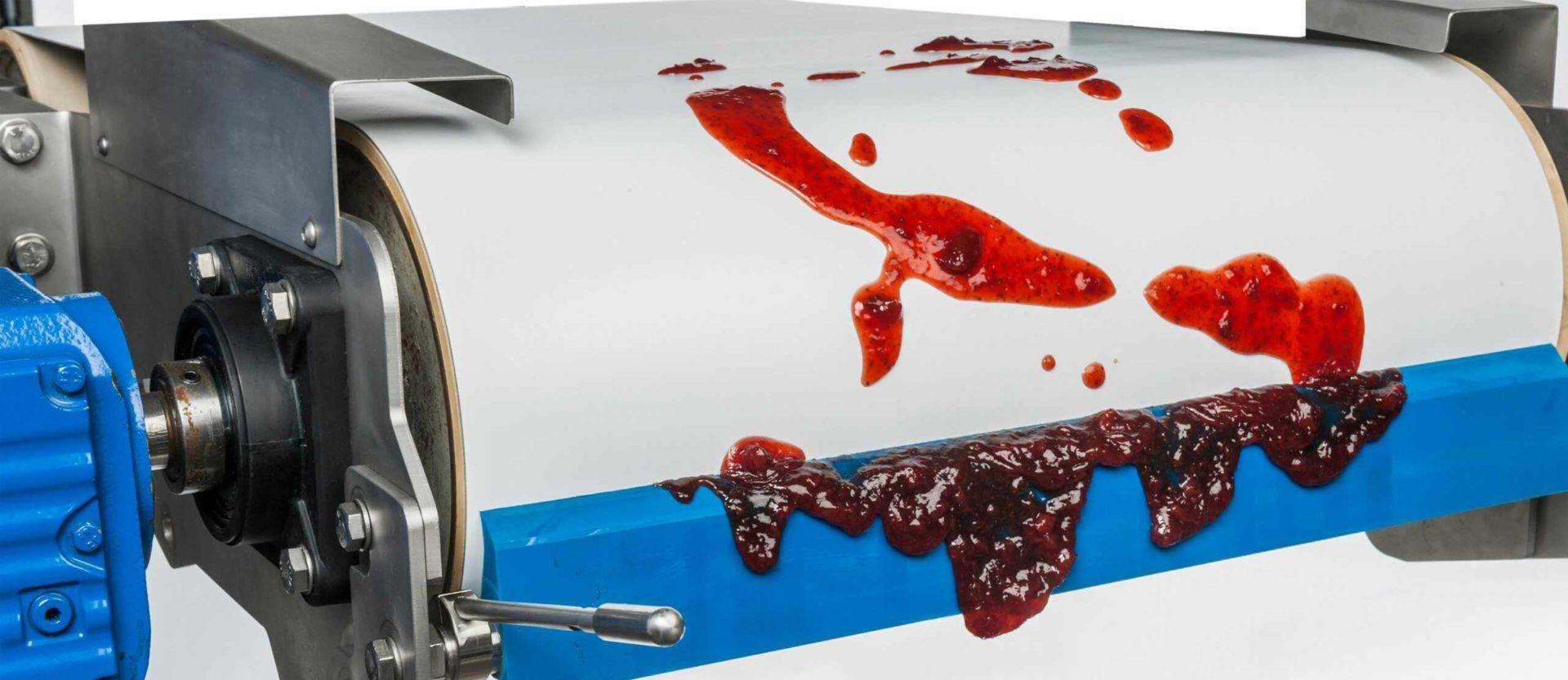

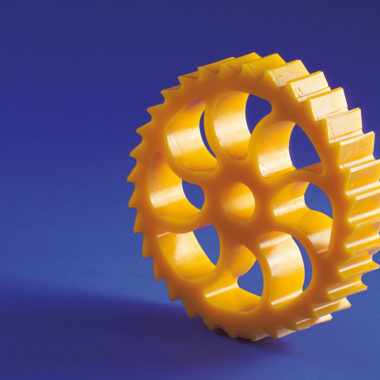

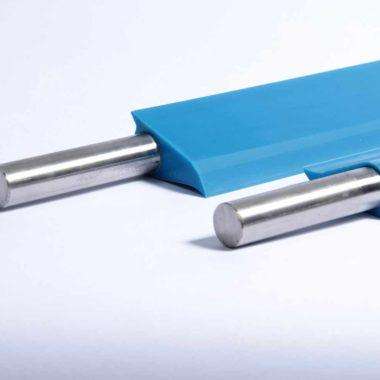

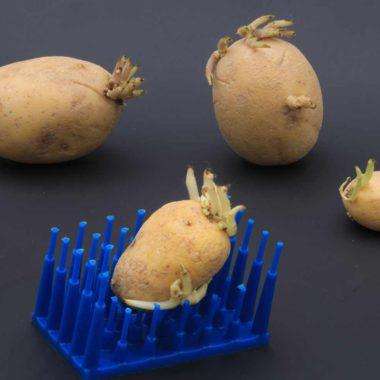

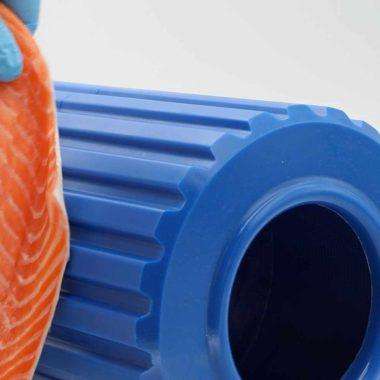

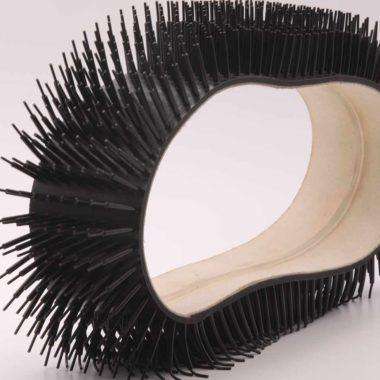

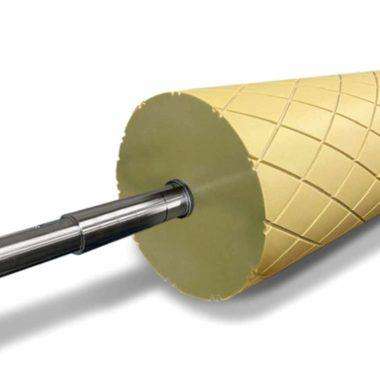

Examples of applications

The [PUR]e focus on development and production

INJECTIONMOULDING

Are you looking for a specialist to manufacture your injection-moulded parts? Then take a look here.

[PUR]CASTING

Do you need large, soft or elastic parts made from polyurethane? Then simply get in touch with us!

[PUR]CYLINDERS

Here are some examples of cylinders with [PUR] coatings. Take advantage of our all-round service.